A challenge that modern pulp and paper mills are facing is to lower operational costs. The highly competitive global market place forces plants to reduce expenditure and extend equipment life. In addition environmental legislation put restrictions on the way that plants operate.

A large portion of rotating equipment in this industry is sealed with mechanical packing. The functional life of mechanical packing has everything to do with the generation and effective removal of frictional heat. Friction is kept to a minimum by the use of low friction materials such as PTFE and graphite as well as the use of friction reducing additives in the packing’s braided structure. Materials with a high coefficient of thermal conductivity are preferred to dissipate heat away from the heat source.

Mechanical Packings are designed to operate in clean fluids. The specific challenge faced in the pulp and paper industry is the high content of solids in the pumped fluid which has a significant effect on the life of the mechanical packing. By nature, packing life is counter proportional with solid content (Fig. 1) .

Fluid particles tend to embed themselves in or accumulate under the packing surface increasing frictional heat. These particles tend to eliminate the positive properties related to friction reduction and heat dissipation given to the packing material and design. Additionally, accumulation of solid particles restrict the fluid circulation required for cooling. Extending the life of mechanical packing is achievable by cleaning up the environment it is operating in.

Fluid particles tend to embed themselves in or accumulate under the packing surface increasing frictional heat. These particles tend to eliminate the positive properties related to friction reduction and heat dissipation given to the packing material and design. Additionally, accumulation of solid particles restrict the fluid circulation required for cooling. Extending the life of mechanical packing is achievable by cleaning up the environment it is operating in.

Traditionally, flush water injection is used to solve this problem. The flush water cools the packing and takes particles away from the dynamic sealing area. However, environmental laws as well as high operational costs associated with flush injection have put restrictions on the amount of water that plants are allowed to use.

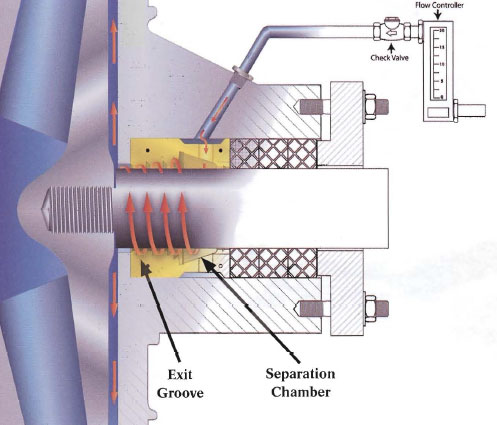

Nowadays, more advanced technologies exist that allow effective solids removal while minimising the amount of flush injection at the same time. One such technology is the SpiraITrac environmental controller. The SpiralTrac technology takes a different approach to cleaning up the mechanical packing’s operating environment. It uses the rotational speed of the fluid including its suspended particles and converts it through centrifugal action into an axial movement.

By design, the SpiralTrac technology takes advantage of the existing rotational flow and directs particles away from the mechanical packing expelling them out of the stuffing box. The challenge has been to find the optimal design for existing pump geometries, speeds, fluid properties and equipment orientation that allows the build up of sufficient kinetic energy to force the particles out of the stuffing box. Computational Fluid Dynamics make it possible to simulate the functioning of the SpiralTrac technology. The various parameters can be toggled in a virtual environment to simulate and visualise the fluid and particle flows.

With the patented SpiralTrac technology water usage can be reduced drastically and in some case be eliminated completely. At the same time, the technology extends the mechanical packing’s life considerably as particles are kept away from the packing set where they could cause damage.

With the patented SpiralTrac technology water usage can be reduced drastically and in some case be eliminated completely. At the same time, the technology extends the mechanical packing’s life considerably as particles are kept away from the packing set where they could cause damage.

The application of the SpiralTrac environmental controller in combination with performance packing truly creates an enhanced sealing solution that offers greatly reduced flush water usage with reduced need for maintenance while extending packing life considerably. It has been successfully applied in refiners, mixers, agitators, pulpers and many other types of equipment commonly found in the pulp and paper industry. It can be supplied either solid or split for ease of installation without the need for equipment disassembly. Materials can be selected according to process requirements from a variety of materials such as stainless steel, glass or carbon filled PTFE.

Controlling Gland Packing By Hans Dekker, Product Manager, Mechanical Packing & Gasketing