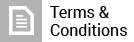

Chesterton 1727 – Multi-Lon® Pump Packing

Chesterton 1727 – Multi-Lon® Pump Packing

A synthetic packing designed to deliver performance equal to synthetics but with the pliability of asbestos.

| Technical Data | |

| Materials | Continuous, synthetic thermoset fibers impregnated with PTFE and a silicone-free break-in lubricant |

| Applications | Water, steam, and chemical pump applications in pulp, paper, and chemical plants |

| Pressure | 15 bar g (200 psig) |

| Speed | 10 m/s (2000 fpm) |

| Temperature | 255˚C (488˚F) |

| Chemical Resistance |

|

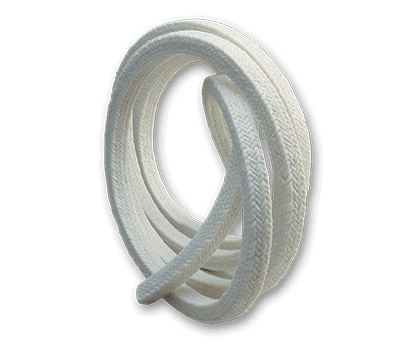

Chesterton 412-W Synthetic Multi-Service Packing

Chesterton 412-W Synthetic Multi-Service Packing

A synthetic coating yarn with a specially formulated break-in lubricant to prevent failure at start-up and maintain continuous lubrication throughout the break-in process.

| Technical Data | |

| Materials | Synthetic composite yarn with PTFE and break-in lubricants |

| Applications | Water, brine, mild acids and alkalis, slurries, and knife gate valves |

| Pressure | 17 bar g (250 psig) |

| Speed | 10 m/s (2000 fpm) |

| Temperature | 230˚C (450˚F) |

| Chemical Resistance | pH 4 to 10 |

Chesterton SuperSetTM Total Sealing Solution Featuring SpiralTrac

Chesterton SuperSetTM Total Sealing Solution Featuring SpiralTrac

Chesterton performance packing sets, in combination with the patented SpiralTrac™ Environmental Controller, reduce flush water consumption and increase equipment service life.

| Common Versions | Applications |

| 1730 SuperSet | General service in slurries and clean fluids |

| 1400R / GraphMax™ SuperSet | Worn equipment, high-speed and high-temperature applications |

| 1760 SuperSet | Highly aggressive chemical environments |

| 1830SSP SuperSet | Bauxite slurries, bottom ash pumps, minerals handling pumps, tailings and other slurries |

Chesterton 1724/324 PTFE Packing

Chesterton 1724/324 PTFE Packing

Chesterton 1724 is a unique PTFE valve packing material specially treated with protective lubricants that will not harden and do not deteriorate in a wide range of chemical applications.

| Technical Data | |

| Applications |

|

| Pressure |

|

| Temperature | 255˚C (488˚F) |

| Chemical Resistance | pH 0 to 14 |